Inspecting sewer lines is a task that requires precision, accuracy, and the right tools. A sewer camera is an indispensable tool for professionals in the plumbing industry, offering a direct glimpse into the depths of sewer lines. These inspections can help identify blockages, damage, and other issues without the need for excavation. Here’s how to use a sewer camera effectively for inspection, including preparation, navigation, analysis, and safety considerations.

Pre-Inspection Preparation: Setting the Stage

Acquiring the Right Equipment

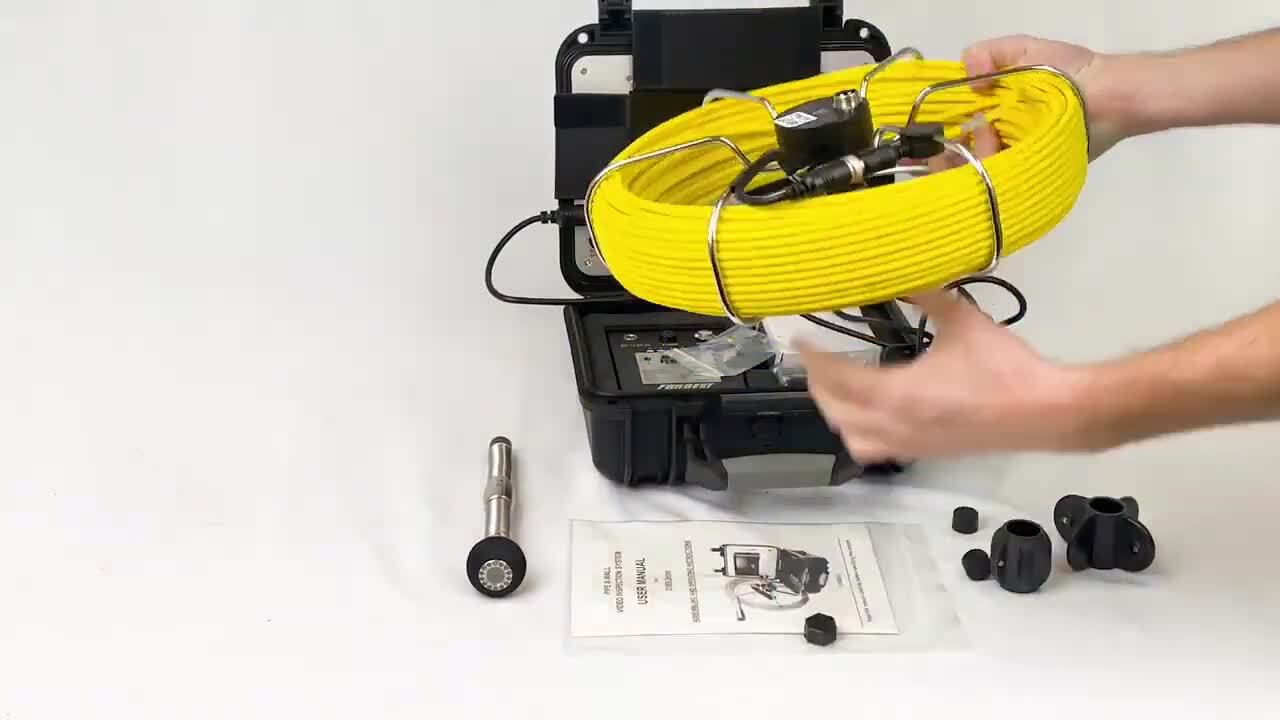

Before undertaking a sewer inspection, ensure you have a high-quality sewer camera system. Choose a camera with a high-resolution lens and adequate lighting to provide the clearest picture possible. Additionally, consider the length of the cable – it should be long enough to reach the full length of the sewer line.

Preparing the Sewer Line

For a successful inspection, clear the sewer line of any obstructions that could interfere with the camera’s movement or obscure its view. Sometimes, a preliminary clean with a hydro jet or auger is necessary. Make sure the camera is fully charged or plugged in, and all connections are secure to prevent equipment failure during the inspection process.

Understanding the Layout

Familiarize yourself with the layout of the sewage system you are inspecting. Knowing the configuration helps in maneuvering the camera and anticipating turns or branches in the line. Accessing plans or maps in advance can save time and prevent potential damage to the camera.

Handling the Camera with Care

Carefully insert the camera into the sewer line. Guide it slowly, using the cable to navigate around corners and through branches. Watch the monitor closely to steer the camera in the right direction and avoid getting it stuck or causing damage to the pipes. Smooth operation is key to an effective inspection.

Analyzing Footage: Identifying Problems

Recognizing Common Issues

As you feed the camera through the line, keep an eye out for common issues such as tree root infiltration, pipe corrosion, or blockages. Good lighting and a clear display are essential for spotting these problems. Pause and inspect any anomalies closely, possibly taking photos or videos for a detailed analysis later.

Documenting Findings

Ensure you record the inspection, as video documentation is crucial for review and formulating a maintenance or repair plan. Take note of the distances indicated on the monitor, as they can help localize the exact areas where issues are detected for targeted repairs. Accurate documentation simplifies the decision-making process and helps in communicating issues to clients or team members.

Post-Inspection Review: Making Decisions

Evaluating the Condition of Pipes

After the inspection, review the footage to evaluate the condition of the sewer pipes. Look for signs of wear and tear, cracks, blockages, or other forms of damage. Assess the urgency of each problem you encounter; not every issue requires immediate attention, but some might demand prompt action to prevent severe damage.

Planning Repairs or Maintenance

Based on your analysis, plan the necessary repairs or maintenance. Present your findings to decision-makers using the documented footage and your expert insights. Provide recommendations for the best course of action, whether it’s a simple clean, repair, or a larger-scale pipe replacement.

Safety and Maintenance: Ensuring Long-Term Utility

Prioritizing Safety During Use

Always prioritize safety when operating a sewer camera. Wear protective gear, avoid contact with hazardous materials, and be cautious around electrical components. Ensure your workspace is secure and that you have backup in case of emergencies.

Caring for Your Sewer Camera

After each use, clean and maintain your sewer camera according to the manufacturer’s guidelines. Regular maintenance keeps the equipment in optimal working condition and extends its lifespan. Inspect cables for wear, keep lenses clean, and store the camera safely to protect it from the elements and potential damage.

Advanced Techniques: Maximizing Camera Potential

Exploring Additional Camera Features

Many modern sewer cameras come equipped with advanced features like self-leveling lenses, locators, and distance counters. Take the time to understand and utilize these features as they can significantly enhance the inspection process. For instance, a self-leveling camera provides a stable and upright image which can be critical when analyzing the pipe’s condition. Using locators can help pinpoint the exact location of a blockage or damage, thus facilitating precise excavation if necessary.

Combining Visual with Data Analysis

Some more sophisticated camera systems offer the ability to not just view the interior of pipes but also collect data about them. This can include information on flow rates, pressure levels, and other variables that can help in diagnosing issues within the sewer line. Integrating both visual inspection and data-driven analysis can lead to a more comprehensive understanding of the pipe’s condition.

Adjusting Inspection Tactics for Varied Piping

Recognize that every sewer line can differ vastly in terms of material, age, and construction. Adjust your inspection approach accordingly. For example, older clay pipes may require a more delicate touch when navigating a camera, whereas newer PVC pipes might allow for a different set of inspection parameters. Being flexible and adapting to the unique nuances of each system is essential for an effective sewer camera inspection.

Client Communication: Reporting and Education

Delivering Clear, Informative Reports

After completing the inspection, compile a clear and concise report for the client. Use the footage and data you’ve collected to explain the condition of the sewer line in understandable terms. Emphasize key points with still images or video clips as necessary. An informative report not only validates your professionalism but also educates the client on their plumbing system.

Advising on Preventative Measures

Offer clients guidance on preventative maintenance to avoid future issues with their sewer lines. Highlight practices that can prolong the life of their plumbing and prevent clogs or damage. Active client engagement not only helps in maintaining sewer health but can build trust and lead to repeat business.

Following Up Post-Inspection

Consider following up with the client after the initial report to see if there are any questions or if they require further services. This step further enhances customer relations and affirms your commitment to their plumbing health and satisfaction. Periodic check-ins can also be an opportunity to remind clients of suggested maintenance or to schedule future inspections.

Effective Inspections for Proactive Solutions

Emphasizing Thoroughness Over Speed

Using a sewer camera effectively means balancing thoroughness with efficiency. Don’t rush the process – a detailed inspection can prevent future problems and save time and money in the long run.

Embracing Technology for Plumbing Excellence

A sewer camera is a vital technology that can elevate the standard of plumbing inspections. By mastering its use, you can provide valuable service, ensuring the integrity of sewer systems and contributing to public health and safety.

Through these steps, plumbers can harness the power of sewer camera technology to perform precise inspections that inform proactive maintenance strategies. Effective use of this tool is not only about handling the equipment; it’s also about interpreting and acting on the findings to maintain a reliable and functional sewer system.